INDIAN ARMED FORCES CHIEFS ON

OUR RELENTLESS AND FOCUSED PUBLISHING EFFORTS

SP Guide Publications puts forth a well compiled articulation of issues, pursuits and accomplishments of the Indian Army, over the years

I am confident that SP Guide Publications would continue to inform, inspire and influence.

My compliments to SP Guide Publications for informative and credible reportage on contemporary aerospace issues over the past six decades.

- Interim Defence Budget 2024-25 — An Analysis

- Union Defence budget 2024

- Indian Army: In quest of greater firepower and policy recommendations for gaps

- Indian Army Annual Press Conference 2024

- 6G will transform military-industrial applications

- Tata Boeing Aerospace Delivers 250 AH-64 Apache Fuselages, Manufactured in India

In the Spotlight: Destined to Win

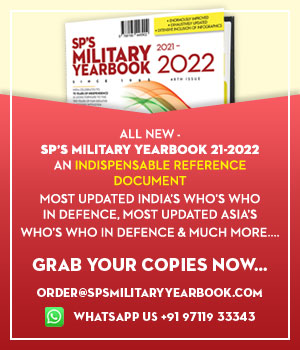

Msta-S self-propelled howitzer

Russia will undoubtedly strengthen its positions in the artillery sector of the world arms market by starting promoting its new 155-mm 2S19M1-155 Msta-S self-propelled howitzer. Specialists in the Rosoboronexport arms exporter believe that deep upgrading and conversion to NATO calibre will greatly increase customer interest in one of the most advanced artillery systems.

The new self-propelled howitzer is a profound upgrade of the 152-mm 2S19 Msta-S howitzer in service with the Russian Army since 1989, which showed itself to best advantage in two military campaigns in the Northern Caucasus. It has established a good reputation for high manoeuvrability and fire accuracy. However, despite impressive technical characteristics and combat capabilities, the 152-mm Msta-S failed to gain popularity in the world arms market. Few countries only have procured small batches of this self-propelled howitzer.

Experts are unanimous in noting that this strange gap in Msta-S exports has been caused by a massive transition from the 152-mm Soviet calibre to 155-mm NATO standard started in the early 1990s. This is why Russia has lost some positions in this market segment. The introduction of the new 155-mm Msta-S must rectify such incongruity.

The new Msta-S has an upgraded targeting and fire control system comprising ballistic computer, topographic survey and orientation system and satellite navigation equipment, designed to provide automatic targeting and data storage for at least 10 fire missions.

The new howitzer can engage targets from closed firing positions and conduct direct fire by day and night and in mountains at elevation angles ranging from - 4 to +70.

It fires the 155-mm HE M1A4 and HE BB M1A4 NATO-standard high-explosive fragmentation rounds at the range of up to 40 km. Provision is made for firing with the Russian laser-guided projectiles Krasnopol-M2. The automatic projectile and semi-automatic propellant charge loading systems facilitate crew work and provide high rate of fire (up to 6-8 rds/min) at all aiming angles. It means that a battery of eight howitzers can bring down up to three tonnes of projectiles in one minute upon a target. When firing at a maximum range, up to 70 projectiles will be up in the air simultaneously before the first projectile hits the target.

The ammunition allowance is carried in the turret and includes 42 155-mm rounds for the howitzer and 300 12.7-mm cartridges for the anti-aircraft machine gun.

At present the new 155-mm Msta-S howitzer is taking part in the important tender for supplying self-propelled howitzers to the Indian Army.

It surpasses its main competitors by rate of fire and cruising endurance, and at the same time it has smaller size and weight. In addition, the Russian howitzer can be loaded and fired in the all-round (360 ) sector in relation to the vehicle centerline.

Experts note that the new Msta-S meets all modern requirements and at the same time surpasses the best world prototypes by a number of characteristics.

It is worthy of mentioning that some customers, for instance India, may find it especially important that the Msta-S chassis is very much unified with the chassis of the T-90S main battle tank (which is being successfully manufactured in that country under licence). Thus it facilitates maintenance, repairs and spares delivery.

New-generation mine-sweeping equipment

Massive use of land mines in wars and armed conflicts, conducting “land mine warfare” necessitate the development of new and improvement of existing minefield breaching devices. Modern engineer equipment is capable of successfully detecting mines, but solving the main task – their neutralization – takes too much time and does not remove threat of explosion. Mineclearing devices are among the safest and most effective means to penetrate minefields and mined terrain areas.

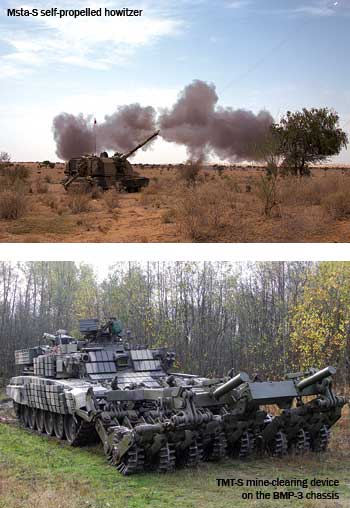

JSC Rosoboronexport is offering its foreign partners a new product – new-generation mine-sweeping equipment. The TMT-S and TMT-K engineer tank mine-clearing devices, adopted by the Russian Land Forces, comprise a set of extra mine-sweeping means providing sweeping for modern and advanced land mines with acoustic, seismic, infrared, magnetic and optical fuzes as well as provide destruction of mine (ground bomb) explosion control wirelines.

The TMT-S mine-clearing roller is designed to breach lanes in minefields. It has three staggered roller sections. Each section includes five rollers mounted in two rows and kinematically connected between each other through side bars. Such a solution provides a dynamic link between rollers in the section and damps explosion energy taken by one roller through the weight of the whole equipment of the section. Rollers in the sections are installed with a minimum clearance between the adjacent rollers which enables anti-tank and antipersonnel mines with fuzes having small pressure plates to be swept. The rollers move freely relative to each other, due to a pivot connection of suspension parts, thus providing more accurate following of terrain accidents. The mine-clearing roller provides a continuous sweeping lane 3.9 m wide.

Its frame carries the EMT electromagnetic attachment designed for sweeping mines with proximity magnetic fuzes. In fact, the electromagnetic attachment is an independent mine-clearing device. When power on, electromagnets generate an alternating electromagnetic field in front of the tank which is equivalent to the magnetic field of a tank, resulting in an explosion of mines with magnetic fuzes before the tank approaches them. The width of the swept lane is 4 meters.

During the use of a cluster device with automatic dispensing of radiating elements intended for sweeping side-hitting mines, pyrotechnic cartridges are fired creating false acoustic and infrared targets. Mines with seismic, infrared or acoustic fuzes are triggered at a distance up to 100 m by ground vibration arising when a vehicle with a mine-clearing device moves and the dispensed pyrotechnic cartridges radiating intensely in the infrared band and generating acoustic radiation trigger.

Cutters-grubbing ploughs are installed in front of the frame. The grubbing ploughs are moved from traveling to working position and back by a mine-clearing roller’s pneumatic system. In working position, the grubbing ploughs are buried in the ground and break mine and ground bomb control wirelines with their knives. The limit depth of cutting a firing wire with cutters-grubbing ploughs is 270 mm.

The TMT-K is a track-width mine plough equipped with a special net attachment for continuous sweeping for scatterable mines in addition to extra equipment similar to that used on the KMT-S. The TMT-K is also fitted with a weight transfer mechanism for additional loading of its working elements that provides increased load under the rollers through transfer of part of weight of the basic vehicle. The weight transfer mechanism helps adjust load under the rollers depending on the soil condition and type and mine laying method (standard or sabotage with a buried fuze pressure plate), which improves minesweeping efficiency, increases travelling speed and maneuverability of the tank with a mine-clearing device.

The design features of the TMT-K provide high-performance minesweeping operations in rough terrain, including on rises, falls and hillsides through an increased lower terrain following limit and individual roller suspension. Spring and pneumatic shock absorbers additionally dissipate mine explosion energy and reduce dynamic loads transmitted by sweeping equipment to the tank.

Both the mine-clearing devices provide emergency uncoupling, changeover of grubbing ploughs from traveling to working position and lane marking without the crew leaving the vehicle.